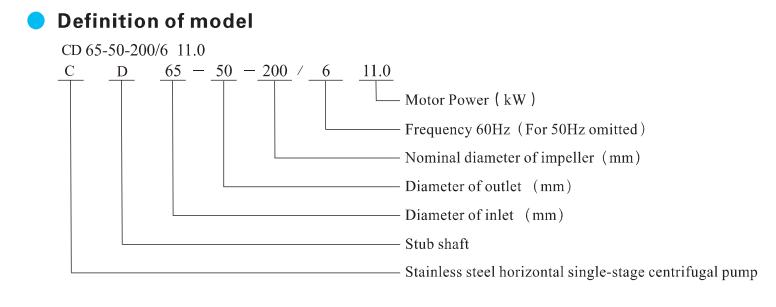

Horizontal Single-stage Centrifugal Pump CD

Introduction

CD type stainless steel horizontal single-stage centrifugal pump is manufactured by advanced technology such as corrosion-resistant plate pressure expansion welding. The stainless steel horizontal single-stage high-temperature pipeline centrifugal pump is made of advanced technology such as stainless steel plate stamping, expansion and welding. It is a new generation of centrifugal pump in China. It is the first new generation of centrifugal pump in China, and can replace the traditional is pump and ordinary anti-corrosion pump. It has beautiful appearance, light structure, high efficiency, energy saving, durability, corrosion resistance, low noise and other characteristics.

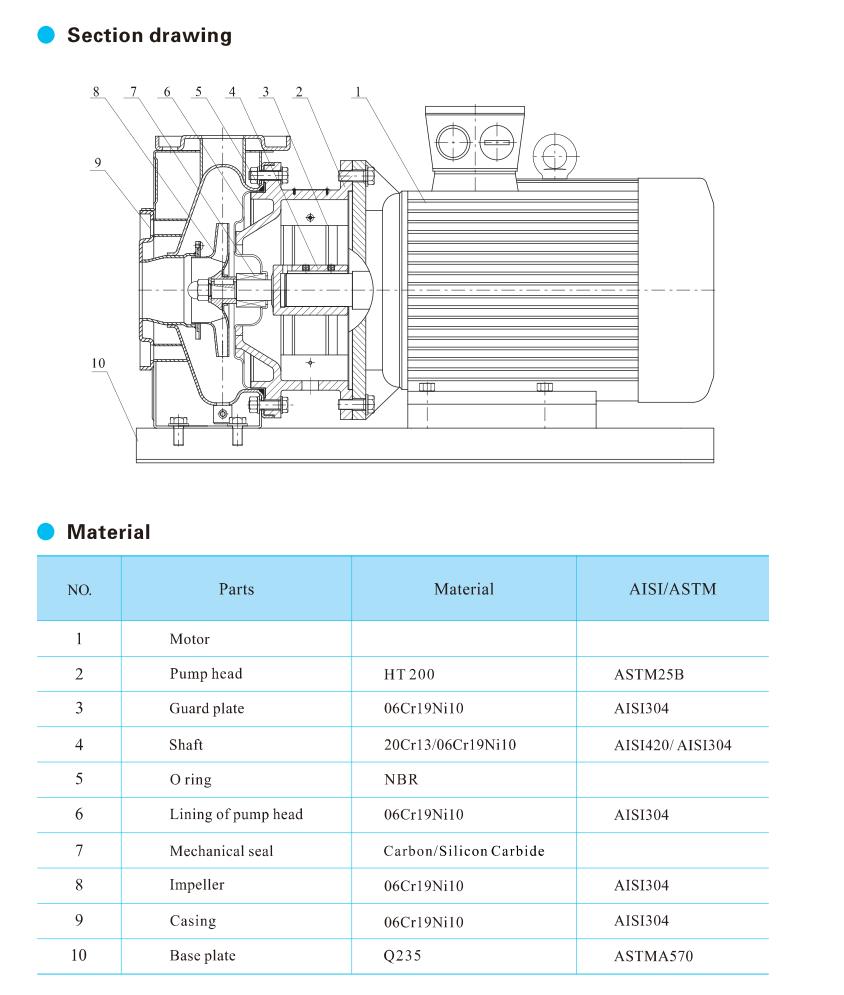

Pump material

Cast iron

Stainless steel (AISI 304, AISI 316)

Duplex stainless steel (2205)

Motor

* Totally enclosed, fan-cooled, 2-pole standard motors

* Enclosure class: IP55

* Insulation class: F

* Voltage:

- 3 x 220 - 240 / 380 - 415 V

- 1 x 220 - 240 V

- available with single-phase motors(0.37 kW-2.2 kW)

Installation conditions

• The pump shall be installed in a ventilated and anti-freezing place;

• The installation of the pump shall ensure that the pump is not affected by the tension of the system pipeline during use;

• If the pump is installed outdoors, it must be equipped with a suitable cover to prevent water ingress or condensation of electrical components;

• In order to facilitate inspection and maintenance, sufficient space must be left around the unit;

• The electrical wiring device shall ensure that the pump is not damaged by phase loss, voltage instability, leakage and overload;

• The pump shall be installed horizontally on the base, with the horizontal direction as the pump inlet and the vertical direction as the pump outlet.

Application

CD Stainless steel horizontal single-stage centrifugal pump is a sort of multifunction product with wide application . It may transmit various medium including water or industrial liquid and is suitable for different temperature , flow rate and range of pressure . Its typical application mainly includes the following aspects.

Water supply : filtration in water works, transportation and subarea water carriage , pressurization of main duct.

Transportation of industrial liquid : water supply of boiler , condensed system , cooling and air conditioning system , machine tool support , light acid and alkali transportation.

Water treatment : distilled water system or separator , swimming pool , etc.

Farmland irrigation , medicine and sanitation , etc.