Efficient Water Distribution and Wastewater Treatment

Efficient Water Distribution and Wastewater Treatment,

High-Rise Building Pump Operation for Efficient Water Distribution and Wastewater Treatment,

PUMP

The vertical pipeline booster pump adopts hydraulic model and is developed and designed with reference to relevant standards as an alternative to SG series pipeline pump. The technical standards, performance parameters, test methods, etc. adopted effectively adopt the ISO standards related to the IS centrifugal pump, with basically the same performance parameters as the IS centrifugal pump, and all its performance indicators meet the design requirements. IRG, LQRG and ISWR hot water pumps are designed with the advantages of structural SGR pump and IR pump, which can replace the use of IR hot water circulating pump and reduce the inconvenience caused by the need to pass cooling water when using IR hot water circulating pump. It is to use air cooling mode, lengthen the distance between the pump and the motor, and protect the motor and bearing to achieve cooling effect

Product features

1. Good air tightness: strict air tightness test shall be carried out from the inlet to the outlet.

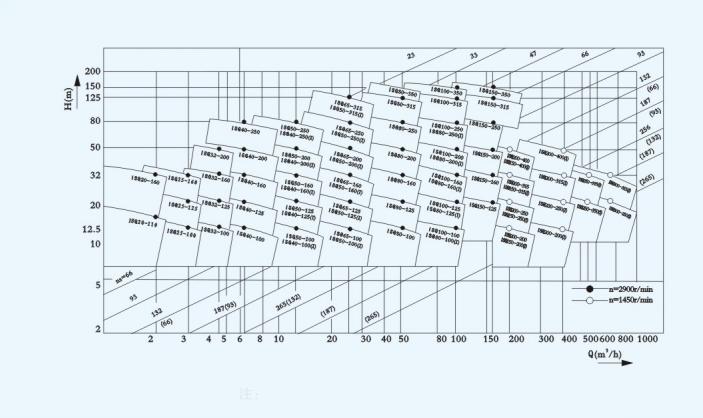

2. The flow is large, and different models can be selected according to needs from 0.3 m3/min to 90 m3/min.

3. Long service life: the electrical life will not be affected because the gas is rich in water,

4. Good maintainability: the motor and transmission components can be removed for maintenance. Simple tools and accessories can be used for self maintenance.

working principle

The biogas booster pump uses the function of mutual extrusion of two rotors to deliver the low-pressure biogas, and generates high-pressure pressure in the process of extrusion.

Applicable scope

It is mainly applicable to high-rise buildings, garden sprinkler irrigation, pipeline pressurization, cold and hot water circulation, transportation of flammable and explosive liquids and corrosive liquids, and various boilers, water supply, heating and ventilation, chemical engineering, and petroleum pipeline equipment.

Ordinary pipe pump is applicable to pressurization of cooling and heating water circulation in high-rise buildings, garden sprinkler irrigation, cooling tower filling, remote water transmission, refrigeration, heating and ventilation, bathroom washing, etc., and the temperature of the medium used is not higher than 80 ℃.

Explosion-proof pipeline pump is applicable to the transportation and pipeline pressurization of petroleum, chemical and non-corrosive flammable and explosive liquids. The temperature of the medium used is not higher than 80 ℃.

Hot water type pipeline pump is applicable to hot water circulation in heating rooms, hotels, boiler hot water supply, and hot water pressurization circulation. The temperature of the medium used is not higher than 140 ℃.

Scope of application

It is applicable to cold and hot water circulating heating of industrial and urban water supply and drainage, urban fire protection, fire protection pressurization, remote water supply, heating, bathroom and other equipment pressurized water supply for high-rise buildings, garden sprinkler irrigation.

High-Rise Building Pump Operation for Efficient Water Distribution and Wastewater Treatment is used to increase the pressure and flow rate of water from a low-pressure source, such as a well or municipal supply, to a higher-pressure destination, such as a shower head or faucet. The pump works by using an electric motor to drive an impeller that pushes water through a pressure tank and out to the destination. The pressure tank helps to maintain a consistent flow rate and pressure by storing a reserve of water that can be quickly delivered to the destination as needed. The pump also typically has a pressure switch that turns the motor on and off based on the pressure of the water in the system, ensuring that the desired pressure is maintained.