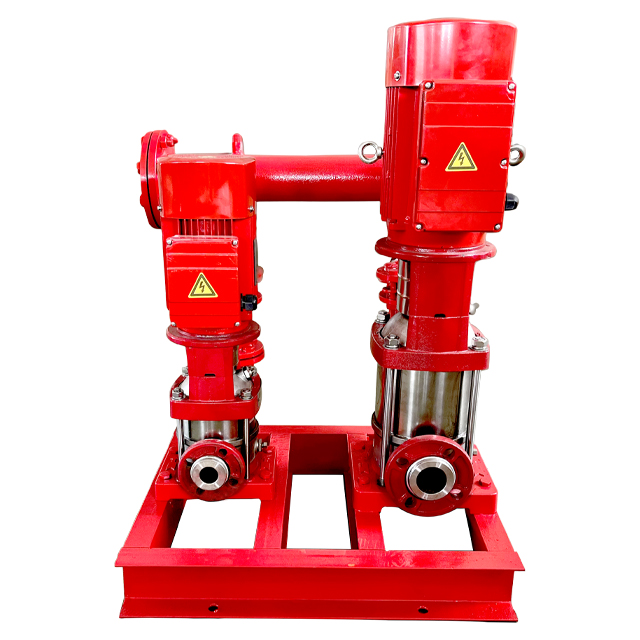

Complete range of fire fighting solutions from horizontal and vertical Fire Pumps to complete pre-packaged Fire Systems

Firefighting units are usually composed of fire pumps, power sources, control cabinets, and related ancillary equipment, with characteristics such as high flow rate, stable performance, and high head. According to different application scenarios and fire protection needs, there are various types to choose from, such as single-stage centrifugal pumps and multi-stage centrifugal pumps. Once a fire occurs, it can be quickly activated to provide sufficient pressure and flow of fire-fighting water for the indoor fire hydrant system, ensuring smooth firefighting work. It can quickly provide a large amount of high-pressure fire-fighting water in emergency situations for cooling, extinguishing and other operations, preventing the fire from expanding and causing more serious accidents such as explosions.