Cast iron sewage pump WQ

Introduction

WQ series submersible sewage pump is the third most advanced sewage pump at home and abroad. It is developed by absorbing the advanced technologies and features of the similar products at home and abroad which based the WQ model, and using the most excellent water power model, special structure and materials, combining the characteristics of sewage and the practical needs of sewage discharging. Its efficiency and performance go beyond the competitive products at home and abroad. The pump has prominent characteristic as high-efficiency, energy-saving, non-clogging, anti-enwinding, and long service life e.g. The pump can be installed with auto-coupling. The series pumps include common type, automatic stir type, automatically-cutting typo.

According to the requirement of market, the pump includes common type (not contains over temperature and leak protection equipment) and full-protection type. The full- protection type can exert its effect used and qualified with the cabinet for submersible pump. Grounding, over-temperature and leakage.

The pump adopts closed flow-path impeller. It adapts to pump liquid containing long fibre and big solid grain.

Application

- Wastewater drainage in factories, construction sites and commercial facilities.

- Drainage system in municipal sewage treatment plants.

- Drainage station in residential quarters.

- Municipal projects.

- Methane pools and field irrigation in countryside

Application

- Wastewater drainage in factories, construction sites and commercial facilities.

- Drainage system in municipal sewage treatment plants.

- Drainage station in residential quarters.

- Municipal projects.

- Methane pools and field irrigation in countryside

Application

- Wastewater drainage in factories, construction sites and commercial facilities.

- Drainage system in municipal sewage treatment plants.

- Drainage station in residential quarters.

- Municipal projects.

- Methane pools and field irrigation in countryside

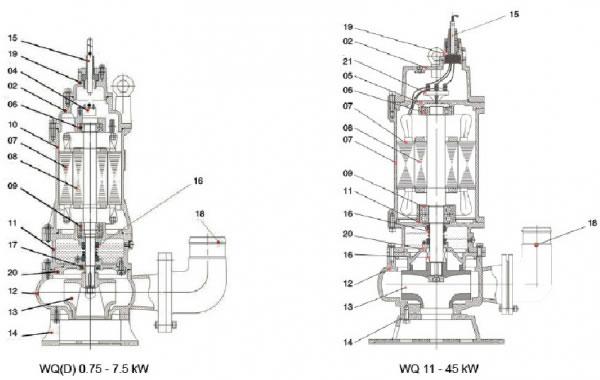

| No. | Part | Material |

| 1 | Handle | Steel |

| 2 | Upper Cover | Cast Iron |

| 3 | Capacitor | |

| 4 | Thermal Protector | |

| 5 | Upper Bearing Seat | Cast Iron |

| 6 | Bering | |

| 7 | Stator | |

| 8 | Rotor | |

| 9 | Bearing | |

| 10 | Motor Body | Cast Iron |

| 11 | Bearing Seat | Cast Iron |

| 12 | Pump Body | Cast Iron |

| 13 | Impeller | Cast Iron |

| 14 | Base | Cast Iron |

| 15 | Cable | |

| 16 | Mechanical Seal | Sic-Sic/Carbon-Ceramic(< 7.5kw) Sic-Sic/Sic-Sic(>7.5kw) |

| 17 | Oil Seal | |

| 18 | Hose Coupling | Cast Iron |

| 19 | Terminal Box | Cast Iron |

| 20 | Seal Bracket | Cast Iron |

| 21 | Wiring Terminal |